CONSIDERATIONS WHEN DECIDING TO SHUT IN OIL AND GAS WELLS

By Holli Cramm, P.E., Vice President – Houston & Completion/Workover/Production Engineer

Given the current industry conditions, many operators are facing the tough decision of whether to shut in their wells. There are many things to consider when deciding which wells to shut in, what measures can be implemented if I shut in the wells, and what procedures do I follow when I am ready to bring the wells back to production.

Given the current industry conditions, many operators are facing the tough decision of whether to shut in their wells. There are many things to consider when deciding which wells to shut in, what measures can be implemented if I shut in the wells, and what procedures do I follow when I am ready to bring the wells back to production.

COMMERCIALITY

The first consideration is commerciality. Do I have adequate storage capacity to continue producing when market options have diminished or completely gone away? If not, what provisions does the lease have for no production? How long can a well be shut in before well work is required, production restored or shut in payments are due? The individual economics of each well should be considered. If there were wells on the border of uneconomic production before the downturn, consider prioritizing my well inventory based on a criterion to be determined. Some wells may need to be plugged. There are benefits to plugging wells now. Plugging wells eliminates future liabilities and current well work pricing are at an all time low.

Every well, every formation and every field will require different evaluation criteria to answer these questions.

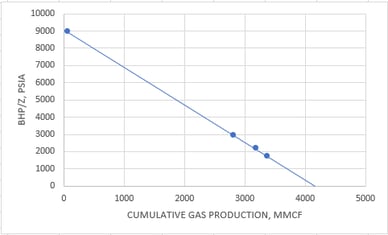

RESERVOIR

One measure to evaluate is the reservoir. Where is the well in its productive life? Does it have adequate reservoir pressure or is it near abandonment pressure? How complex is the completion? Is it completed in multiple zones or layers of the same reservoir? Is crossflow between intervals a problem? Was the well hydraulically fractured? How much water was recovered after the frac job? Could the remaining frac fluids create damage now that fluid flow has stopped? Is fines migration a possibility? As the reservoir fluids segregate, could scale, precipitates and emulsions form barriers downhole?

MECHANICAL STRUCTURE

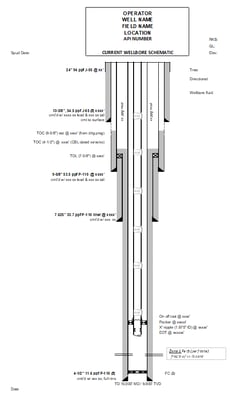

Mechanically, it is critical to consider the wellbore equipment and surface equipment. Was the well designed with extended shut in conditions in mind? What are the differential pressures that the downhole completion equipment can withstand? With the possibility of fluid segregation, what corrosion issues may arise? Is the equipment appropriate and competent for its new purpose? Can surface equipment withstand the long-term higher shut in pressures? Do facilities and flowlines need to be purged or pickled to reduce the opportunity for failures?

Even though cash flow is negatively impacted when wells or whole fields are shut in, there are operational procedures that can be implemented to provide benefit when the fields come back online. Use this time to ensure well files and schematics are up to date. Study the well records to determine specific information that should be collected; shut in pressure surveys, pressure buildup analyses and interference surveys will provide crucial information that will provide details that can be used to enhance the ultimate field recovery. Diagnostic operations such as checking the plug back depth, running tubing/casing caliper surveys, and logging can be used to improve production or minimize future failures. Surface equipment should be properly maintained and necessary enhancements made during the shut in.

When bringing the wells back online, it is imperative to follow the unique well plan created during the shut in taking into consideration individual wellbore construction and reservoir parameters. Has the facility been checked to minimize down time during field restart? Each facility hiccup can generate wellbore damage to an already stressed system. Substandard production rates are a possibility, realize that remedial operations may be necessary, including mechanical or chemical enhancements, once the well begins to produce.

Stokes & Spiehler is here to help you get your fields back to their optimum production. Taking care of oil and gas wells is what we do today and every day. We have engineers and field personnel that can help you weather the storm, and help make the tough decisions so that your oil and gas assets are protected.

Click the "Contact Us" button below and write us a brief message. We look forward to helping you manage your oil and gas fields during this difficult time.